Table of Contents

Commit 2019-04-09

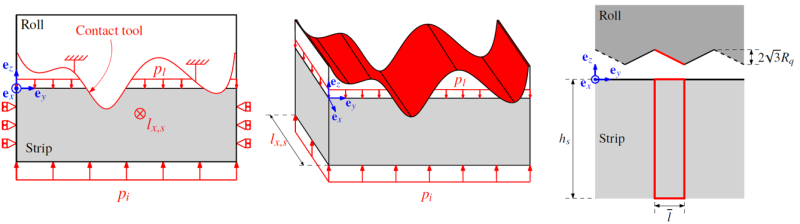

In this commit, the asperity flattening model (oo_meta/aspCrushing/boemer, commit 3186) was updated. This version has to be used with version 1531 of Metalub to run the coupling procedure. Additional information can be found in Boemer's thesis document. The following modifications were applied to the model, which is represented in the following figure, and to the general file structure.

Modifications of the model

The model is defined in the script oo_meta/aspCrushing/boemer/tools/aspFlattening.py (previously flattening.py), which uses mainly the scripts aspGeoMesh.py (previously, geoLinear.py) to build the geometry and mesh, and extractors.py to extract the data of the simulation. The following changes were made in the model:

- The lubricant pressure is only applied where the roll is not in contact with the strip via the ContactTractionElement. This element can be included in the computation by activating the lubricant pressure at the transition from contact to no contact or not by setting the variable

p['tractAtTransOn']toTrueorFalse, respectively; - The applied lubricant pressure can be reduced to have no indeterminate separation between the roll and the strip, when it becomes equal to the interface pressure, by specifying the percentage of lubricant pressure that is applied via the parameter

p['pLFactor']; - In addition to the computation via the intersections of the roll and strip profiles, the relative contact area can be calculated by the contact status and the projection of the associated area onto the horizontal by setting

p['extrA']to'status' instead of'intersection'; - The specific values in this model are based on those of test 5B-4 of the experimental campaign at Maizières-lès-Metz in 2014, which were adjusted to have triangular asperities and no thermoplasticity in the flattening model. Hence, Autesserre hardening (i.e. SMATCH), was replaced by Ludwig hardening (elastoplastic component of Johnson-Cook), which is wrongly called Swift hardening in Metafor.

- The previous extraction method is required if the contact gap is controlled by the augmented Lagrangian method, which was also added to this model, before noticing that the results are mesh-dependent, when the lubricant pressure becomes equal to the interface pressure;

- The position of the node of the upper edge of the strip are only extracted when

p['extrEdge']is set toTrue, in order to minimize the data, which is written to file during a run of the coupling procedure; - Specific time steps can be written to file by setting the elements of the list

p['tExtr'].

General modifications

- The regression tests are based on test 5B-4 of the experimental campaign at Maizières-lès-Metz in 2014. The data in the folder

bcwas created by the Metalub model of this test (without thermoplasticity and with a triangular asperity profile, as explained in Boemer's thesis document); - The tests were renamed to

dry.pyandlub.pyinaspCrushing/boemer/teststo be more concise; - The file, which contains the out-of-plane length of the strip portion, i.e.

res_bc_epsx.asciiis renamed tores_bx_lxs, to be coherent with the notations. While $\epsilon_{x}$ is a deformation, $l_{x,s}$ is a length (of the strip); tools/flattening.pyandtools/geoLinear.pywere renamed totools/aspFlattening.pyandtools/aspGeoMesh.py, to be more precise and since more complex geometries than a linear triangular asperity profile can be modeled.