Table of Contents

Yield Stress

The class YieldStress manages the yield stress used in the plastic criterion, whether plastic (isotropic hardening), visco-plastic (Perzyna as additive, Cowper-Symonds as multiplicative or ZerilliArmstrong, JohnsonCook, … as flow stress models)

$$ \sigma_{yield} = \sigma_{yield} (\bar{\varepsilon}^{vp}, \dot{\bar{\varepsilon}}^{vp}, grainSize, ...) $$

The laws implemented in Metafor are described below

IsotropicHardening

In order to simplify most of the test cases, the IsotropicHardening classes (Isotropic hardening) derive from the YieldStress class.

$$

\sigma_{yield} = \sigma_{isoHard}( \bar{\varepsilon}^{vp})

$$

Consequently, isotropic hardening is directly referred in the material as a YieldStress.

GsIsoHYieldStress

Yield Stress defined by an isotropic hardening:

$$ \sigma_{yield} = \sigma_{isoHard}( \bar{\varepsilon}^{vp}) + \sigma_{grainSize}( \bar{\varepsilon}^{vp}, \dot{\bar{\varepsilon}}^{vp}, grainSize ) $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| Number of the isotropic hardening law | IH_NUM | |

| Number of the grain size evolution law | GS_NUM |

PerzynaYieldStress

Yield Stress defined by an isotropic hardening and a visco-plastic Perzyna yield stress:

$$ \sigma_{yield} = \sigma_{isoHard}( \bar{\varepsilon}^{vp}) + K (\dot{\bar{\varepsilon}}^{vp})^M \left(\bar{\varepsilon}^{vp}\right)^N $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| Number of the isotropic hardening law | IH_NUM | |

| $K $ | PERZYNA_K | TM/TO |

| $M $ | PERZYNA_M | TM/TO |

| $N $ | PERZYNA_N | TM/TO |

GsPerzynaYieldStress

Yield Stress defined by an isotropic hardening, a visco-plastic Perzyna yield stress and a “grain size” stress:

$$ \sigma_{yield} = \sigma_{isoHard}( \bar{\varepsilon}^{vp}) + K (\dot{\bar{\varepsilon}}^{vp})^M \left(\bar{\varepsilon}^{vp}\right)^N + \sigma_{grainSize}( \bar{\varepsilon}^{vp}, \dot{\bar{\varepsilon}}^{vp}, grainSize ) $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| Number of the isotropic hardening law | IH_NUM | |

| Number of the grain size evolution law | GS_NUM | |

| $K $ | PERZYNA_K | TM/TO |

| $M $ | PERZYNA_M | TM/TO |

| $N $ | PERZYNA_N | TM/TO |

JohnsonCookYieldStress

Johnson-Cook visco-plastic law:

\begin{multline} \sigma_{yield}= \left( A+B \left( \bar{\varepsilon}^{vp} \right)^n \right) \left(1+C\ln\left(\dfrac{\dot{\bar{\varepsilon}}^{vp}}{\dot{\varepsilon}_0}\right)+C_2\left(\ln\left(\dfrac{\dot{\bar{\varepsilon}}^{vp}}{\dot{\varepsilon}_0}\right)\right)^2\right) \\ \left( 1- \left( \dfrac{T-T_{room}}{T_{melt}-T_{room}} \right)^m \right) \end{multline}

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $A $ | JC_A | TM/TO |

| $B $ | JC_B | TM/TO |

| $n $ | JC_N | TM/TO |

| $m $ | JC_M | TM/TO |

| Room temperature $T_{room}$ | JC_TROOM | TM/TO |

| Melting temperature $T_{melt}$ | JC_TMELT | TM/TO |

| $C $ | JC_C | TM/TO |

| $C_2 $ | JC_C2 | TM/TO |

| $\dot{\varepsilon}_0$ | JC_EPSP0 | TM/TO |

JohnsonCookMecYieldStress

Isotherm version of the Johnson-Cook visco-plastic law :

$$ \sigma_{yield}= \left( A+B \left( \bar{\varepsilon}^{vp} \right)^n \right) \left(1+C\ln\left(\dfrac{\dot{\bar{\varepsilon}}^{vp}}{\dot{\varepsilon}_0}\right)+C_2\left(\ln\left(\dfrac{\dot{\bar{\varepsilon}}^{vp}}{\dot{\varepsilon}_0}\right)\right)^2\right) $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $A $ | JC_A | TM/TO |

| $B $ | JC_B | TM/TO |

| $n $ | JC_N | TM/TO |

| $C $ | JC_C | TM/TO |

| $C_2 $ | JC_C2 | TM/TO |

| ${\dot\varepsilon}_{0}$ | JC_EPSP0 | TM/TO |

PowJohnsonCookYieldStress

Power version of the Johnson-Cook visco-plastic law (PP implementation):

$$ \sigma_{yield}= \left( A+B \left( \bar{\varepsilon}^{vp} \right)^n \right) \left(1+\dfrac{\dot{\bar{\varepsilon}}^{vp}}{\dot{\varepsilon}_0}\right)^C \left( 1- \left( \dfrac{T-T_{room}}{T_{melt}-T_{room}} \right)^m \right) $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $A $ | JC_A | TM/TO |

| $B $ | JC_B | TM/TO |

| $n $ | JC_N | TM/TO |

| $m $ | JC_M | TM/TO |

| Room temperature $T_{room}$ | JC_TROOM | TM/TO |

| Melting temperature $T_{melt}$ | JC_TMELT | TM/TO |

| $C $ | JC_C | TM/TO |

| $\dot{\varepsilon}_0$ | JC_EPSP0 | TM/TO |

ZerilliArmstrongYieldStress

Zerilli-Armstong visco-plastic law:

$$ \sigma_{yield} = \sigma_0 + C_5 \left( \bar{\varepsilon}^{vp} \right) ^{n_1} + C_2 \left( \bar{\varepsilon}^{vp} \right)^{n_2} \exp \left( -C_3 T + C_4 T \ln \dot{\bar{\varepsilon}}^{vp} \right) $$

For FCC metals, $C_5=0$. For BCC metals, $n_2=0$.

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $\sigma_0$ | ZA_SIGMA0 | TM/TO |

| $C_5$ | ZA_C5 | TM/TO |

| $n_1$ | ZA_N1 | TM/TO |

| $C_2$ | ZA_C2 | TM/TO |

| $n_2$ | ZA_N2 | TM/TO |

| $C_3$ | ZA_C3 | TM/TO |

| $C_4$ | ZA_C4 | TM/TO |

CowperSymondsYieldStress

Cowper-Symonds visco-plastic law.

$$ \sigma_{yield}= \sigma_0 \left( 1 + \left(\dfrac{\dot{\overline{\varepsilon}}^{vp}}{D}\right)^{\frac{1}{p}} \right) $$

where $\sigma_0$ is the static yield stress, whose evolution is often given by a piecewise linear function.

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| Number of the hardening law | IH_NUM | |

| $D $ | CS_D | TM/TO |

| $p $ | CS_P | TM/TO |

ViscoKocksMeckingYieldStress

Description

Visco-plastic extension of the “Kocks-Mecking” isotropic hardening law.

$$ \sigma_{y} = \sigma_{y}^{0} + \sigma_{v} [1-exp(-\frac{\Theta_{0}}{\sigma_{v}} \bar{\varepsilon}^{vp}) ] \;\;\; si \;\;\; \sigma_{y} \leq \sigma_{y}^{tr} $$

$$ \sigma_{y} = \sigma_{y}^{tr} + \Theta_{IV} \left( \bar{\varepsilon}^{vp} - \bar{\varepsilon}^{vp}_{tr}\right) \;\;\; si \;\;\; \sigma_{y} > \sigma_{y}^{tr} $$

where $\sigma_{y}^{tr} $ is a transition yield stress, computed to guarantee continuity between both phases:

$$ \sigma_{y}^{tr} = \sigma_{y}^{0} + \sigma_{v}\frac{(\Theta_{0}-\Theta_{IV})}{\Theta_{0}} $$

and where $\bar{\varepsilon}^{vp}_{tr}$ is the corresponding plastic strain:

$$ \bar{\varepsilon}^{vp}_{tr} = \frac{\sigma_{v}}{\Theta_{0}} \ln \left(\frac{\Theta_{0}}{\Theta_{IV}}\right) $$

The viscous component of the yield stress is hidden in the calculation of the saturation stress:

$$ \sigma_{v} = \sigma_{v0} \left ( \frac{\dot{\bar{\varepsilon}}^{vp}}{\dot{\bar{\varepsilon}}^{vp}_{0}} \right ) ^{\left (\frac{kT}{A} \right )} $$

$k$ : Boltzman's constant = $1.381e^{-23} \mbox{J}/\mbox{K}$

$T$ : Temperature K (CAREFUL in Kelvin : requires the definition of the temperature in the material)

$A$ : Activation energy (material constant)

${\dot{\bar{\varepsilon}}^{vp}_{0}}$ : reference plastic strain rate (= $1.e7$)

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $\sigma_0$ | IH_SIGMA0 | TM/TO |

| $\Theta_{0}$ | KM_THETA0 | TM/TO |

| $\Theta_{IV}$ | KM_THETA4 | TM/TO |

| $\sigma_{v0}$ | KM_SIGV0 | - |

| ${\dot{\bar{\varepsilon}}^{vp}_{0}}$ | KM_DEVPL0 | - |

| $k$ : Boltzman's constant | KM_BOLTZMANN | - |

| $A$ | KM_A | - |

ViscoKocksMecking2YieldStress

Description

Second visco-plastic extension of the “Kocks-Mecking” isotropic hardening law, to match the Ta6V better.

No fourth step

The basic equation is still: $$ \sigma_{y} = \sigma_{y}^{0} + \sigma_{v} \left [1-exp \left (-\frac{\Theta_{0}}{\sigma_{v}} \bar{\varepsilon}^{vp}\right ) \right ] $$

Both plastic strain rate and temperature dependency are hidden in the calculation of the Voce stress $\sigma_{v}$. If this Voce stress is plotted as a function of the $g$ parameter, defined as:

$$ g = \frac{kT}{\mu b^3} \ln \left ( \frac{\dot{\bar{\varepsilon}}^{vp}_{0}}{\dot{\bar{\varepsilon}}^{vp}} \right ) $$

where

$b$ : is the norm of the Burgers vector

$k$ : is the Boltzmann's constant

(for Ta6V, $ \frac{k}{b^3} ~ 1.135 $, in “$\mbox{Mpa}$”)

$T$ : Temperature K (CAREFUL in Kelvin : requires the definition of the temperature in the material)

$\mu$ : Elastic shear modulus of the material (requires a new definition of Young's modulus and Poisson ratio in the KM2 law!!!)

$\dot{\bar{\varepsilon}}^{vp}_{0}$: reference plastic strain rate (= $1.e7$)

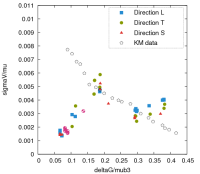

the following figure is obtained:

KocksMecking usually predicts a linear evolution (KM data). However, the Ta6V trial data are the colored dots. The evolution is more in broken lines, defined as follow:

$G12$ and $G23$ are defined as the transition values between the three areas:

$$ \frac{\sigma_{v}}{\mu} = A1 \; g + B1 \;\;\;si\;\;\; g < G12 \\ \frac{\sigma_{v}}{\mu} = A2 \; g + B2 \;\;\;si\;\;\; G12 < g < G23 \\ \frac{\sigma_{v}}{\mu} = A3 \; g + B3 \;\;\;si\;\;\; G23 < g $$

Finally, the apparition of plasticity was observed to depend on strain rate and temperature (here, the temperature dependency is explicitly defined, but it could be done implicitly):

$$\sigma_0 = A + B T + (C + D T) \ln \left (\dot{\bar{\varepsilon}}^{vp}\right ) $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $ A $ | IH_SIGEL_A | - |

| $ B $ | IH_SIGEL_B | - |

| $ C $ | IH_SIGEL_C | - |

| $ D $ | IH_SIGEL_D | - |

| $ A1 $ | KM2_SIGVOCE_A1 | - |

| $ B1 $ | KM2_SIGVOCE_B1 | - |

| $ G12 $ | KM2_SIGVOCE_G12 | - |

| $ A2 $ | KM2_SIGVOCE_A2 | - |

| $ B2 $ | KM2_SIGVOCE_B2 | - |

| $ G23 $ | KM2_SIGVOCE_G23 | - |

| $ A3 $ | KM2_SIGVOCE_A3 | - |

| $ B3 $ | KM2_SIGVOCE_B3 | - |

| $\frac{k}{b^3}$ | KM2_BOLTZMANN_BURGER3 | - |

| Young's Modulus | KM2_ELASTIC_MODULUS | - |

| Poisson ratio | KM2_POISSON_RATIO | - |

| $\Theta_{0}$ | KM_THETA0 | TM/TO |

| ${\dot{\bar{\varepsilon}}^{vp}_{0}}$ | KM_DEVPL0 | - |

SellarsTegartYieldStress

Yield Stress used for hot rolling defined by :

- a viscous power term :

$$ S0 = \sqrt{3} \; KK (\sqrt{3} \;\dot{\bar{\varepsilon}}^{vp})^{M0} $$

- a viscous asinh Term :

$$ Ss = As \; asinh((\frac{\dot{\bar{\varepsilon}}^{vp}}{Zs})^{Ms}) $$

- for the Yield Stress computed by (using a Voce hardening term):

$$ \sigma_{yield} = S0 + (Ss - S0) (1-e^{-C \; \bar{\varepsilon}^{vp}})^{R} $$

Parameters

| Name | Metafor Code | Dependency |

|---|---|---|

| $KK $ | SELLARSTEGART_KK | TM/TO |

| $M0 $ | SELLARSTEGART_M0 | TM/TO |

| $As $ | SELLARSTEGART_AS | TM/TO |

| $Zs $ | SELLARSTEGART_MS | TM/TO |

| $Ms $ | SELLARSTEGART_ZS | TM/TO |

| $C $ | SELLARSTEGART_R | TM/TO |

| $R $ | SELLARSTEGART_C | TM/TO |

PythonYieldStress

User defined Yield Stress by a pythonDirector : Python Director allows user to define their own Yield Stress law. Four functions has to be defined in the Python Class : a constructor (init), a destructor (del) that must never be called, and the computation functions : getYieldStress (returning YieldStress) and getYieldHardening (returning h). See the example below of a Perzyna law :

class MyYieldStress(PythonYieldStress):

def __init__(self, _no, _svm0, _h, _K, _m):

print("MyYieldStress: __init__")

PythonYieldStress.__init__(self,_no)

self.svm0 = _svm0

self.h = _h

self.K = _K

self.m = _m

def __del__(self):

print("MyIsoH : __del__")

print("callToDestructor of MyYieldStress not allowed. Add MyIsoH.__disown__()")

input('')

exit(1)

def getYieldStress(self, evpl, deltaEvpl, dTime, yieldGPState, pLaw):

#print "MyYieldStress compute Yield Stress"

if dTime > 0.0:

dEvpl = deltaEvpl/dTime

else:

dEvpl = 0.0

sigH = self.svm0+evpl*self.h

sigV = self.K*pow(dEvpl, self.m)

#yieldGPState.setVpStress(sigV)

return sigH+sigV

def getYieldHardening(self, epl, deltaEvpl, dTime, yieldGPState, pLaw) :

if dTime > 0.0:

dEvpl = deltaEvpl/dTime

h = self.h + (self.K*pow(dEvpl, self.m-1))/dTime

else:

dEvpl = 0.0

h = self.h

return h