This is an old revision of the document!

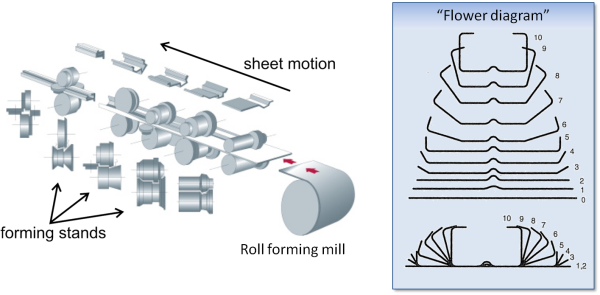

Roll forming

A metal strip is incrementally bent by sets of rolls (called “forming stands”) until the desired cross section is obtained.

Symmetrical U-channel

Process parameters

- Experimental mill (ArcelorMittal R&D, Montataire, France).

- 6 stands (15°, 32°, 50°, 68°, 80°, 90°).

- Final bending radii: 6 mm

- Inter-stand distance : 0.5 m

- Sheet : 2000 x 200 x 1.6 mm

- Coulomb friction m = 0.2

- DP980 steel (sY0 = 697.34 MPa).

Numerical parameters

- Symmetry.

- Friction drives the sheet.

- Two layers of EAS elements.

- Dynamic implicit scheme (Chung-Hulbert).

Classical transient Lagrangian model

<html>

<iframe width=“560” height=“200” src=“www.youtube.com/embed/YFefQOfrAs4” frameborder=“0” allowfullscreen></iframe>

</html>

</WRAP>

The proposed ALE model of continuous roll forming

<html>

<iframe width=“560” height=“200” src=“www.youtube.com/embed/2v0BybZ6RDU” frameborder=“0” allowfullscreen></iframe>

</html>

</WRAP>

—-

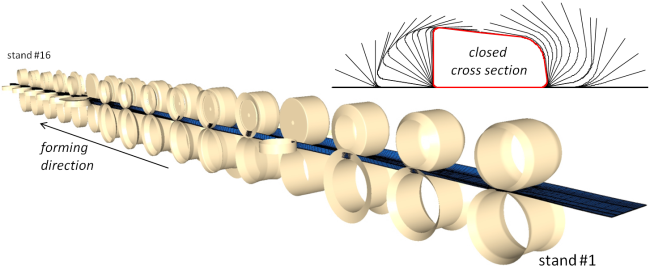

===== Rocker pannel =====

Process parameters

- 16 stands – unsymmetrical shape.

- Material: DP980.

- Sheet: 5950 x 165 x 1.5 mm

Mesh

- 1 FE through the thickness.

- FE length: from 3mm to 30mm

- 155 652 dofs.

<html> <iframe width=“480” height=“360” src=“www.youtube.com/embed/tAXxNkLpm20” frameborder=“0” allowfullscreen></iframe> </html> </WRAP>